|

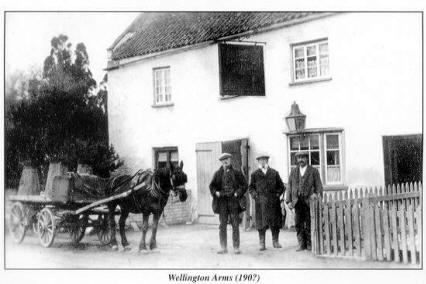

A far cry from the horse and cart days of circa 1900, when local farmers

brought their milk direct to the dairy. Still warm from the cow!

You cant even stop on the way home

for a quick one at the 'Welly' now! |

In the very early days, local

farmers supplied the factory with the milk for cheesemaking, bringing it

by horse and cart and even on hand trucks. In those days milk was moved

about in 17 and 20 gallon churns.

Eventually, increasing demand required milk to be collected from an

expanding area of farms. And the Cheddar Valley Dairy set up collection

rounds to pick up the milk direct from the farms. Milk stands were a

common sight at nearly every dairy farm.

Even so, many local farmers still brought their milk direct to the dairy

right up until Milk Marketing Board took over the collection and

distribution of raw milk in the late sixties.

With the installation of conveyer chains and churn washing

machinery to speed up the handling of an ever increasing

intake at the dairy, the 20 and 17 gall steel churns were phased

out in favour of 12 gall and later standardised to 10 gallons. and

eventually 10 gallon aluminium churns.

These "Alloys" were a godsend to the drivers who collected farm

milk. Trying to lift a full 12 gall steel churn, full of milk

onto a lorry while perched on a wobbly trolley or a rickety old

milk stand, I can assure you was not easy or fun!

(And I've got the hernia to prove it)! |

George Emery and friend with one of the early milk lorries.

Photo courtesy: Margery Fear. |

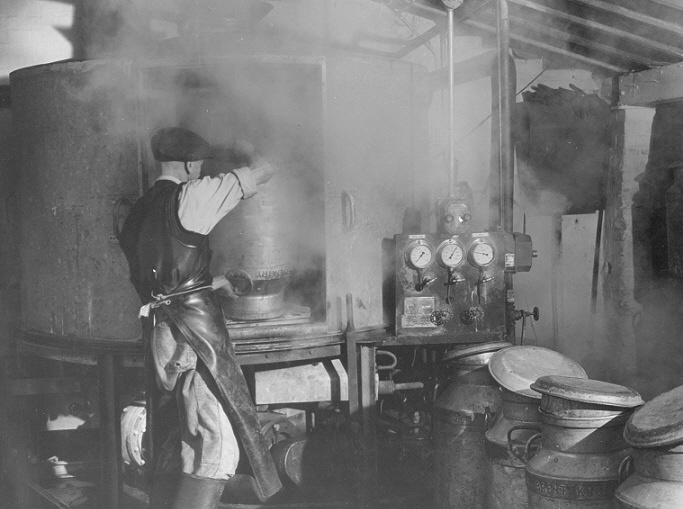

Above. Milk arrives at the dairy c. 1950

Right. A busy milk intake circa 1970.

photo: courtesy R Brown. |

A typical scene with incoming milk being

unloaded, weighed, sampled and sniffed! |

On arrival at the factory, every churn was visually checked

against the label for correct gallonage and farmers totals. The raw milk was then

segregated by the colour of the label, into ordinary, channel island,

tuberculin tested and non-tuberculin tested. (All milk now is from

tuberculosis free herds).

Before it could be used, it had to be sampled and sniffed! Each

farmers milk was sampled for keeping quality, butterfat content and the

use of antibiotics and penicillin etc. (Milk containing penicillin would

kill the starter used for cheesemaking and could ruin production. And the

cheese makers were not happy chappies when this happened)!

Each churn was also visually checked and sniffed for taints, colour and

foreign objects. We always said. "Art' Popham could spot a drowned

mouse or smell a dodgy churn

of milk from 50 paces". Any rejected churns were given a red label and

returned to the farmer next morning.

|

Arthur Popham seen here in the 1950's, was in charge of intake and

pasteurising for over 40 years

|

Percy Hatcher washes churns in a rotary churnwasher.

Photos courtesy: R Brown.

|

|

Later the above processes seen here, were replaced

with an in-line churn tipping and washer system which did the whole

thing mechanically!

Once accepted, the milk was tipped into a tank from where it would

be pumped via the pasteuriser to the various departments and

holding tanks, depending on the type of milk and what it was to be

used for. eg. Butter, cream, cheese or bottling. |

|

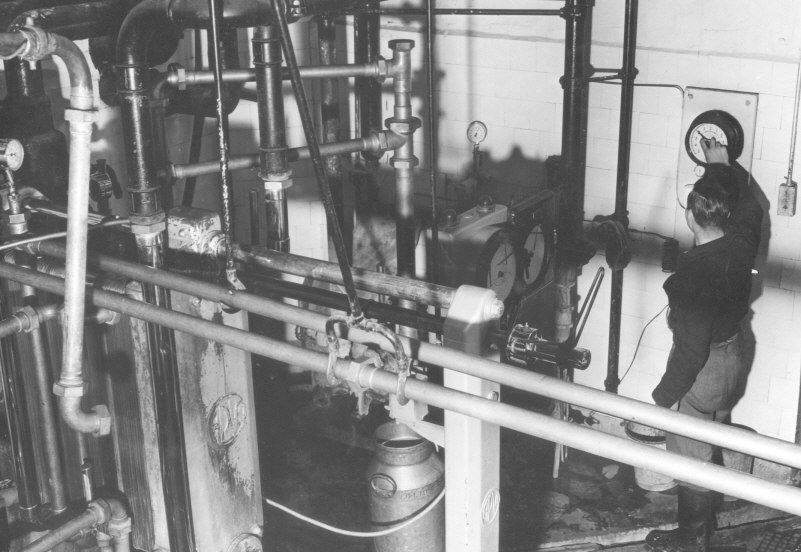

Pasteurising...

All I know is... Milk is pasteurised by heating it, usually to over

70°C for 15 seconds. This gets rid of any food poisoning bacteria in

the milk and reduces the bacteria that make milk go off. So

pasteurising milk makes it safer to drink and makes it last longer.

To me, the pasteuriser was just a mass of valves and pipes! And I was

always in awe of how the operators knew which valves or pipes led to

where?

|

In the late 1960's the collection and distribution of raw farm milk was

taken over by the Milk Marketing Board. And from this time all milk used

at the dairy was supplied by MMB. |

Soon after taking over the collection of farm milk, the MMB phased out

churns and converted to collection in bulk tankers.

Many of the small farmers who eked out a living from six or seven

churns, gave up milking at this time, because they could not afford the

collection charges introduced, or accommodate new

refrigerated storage tanks or create the tanker access etc. needed for the

change over.

Photos. J Rigarlsford |

Over the years the farm collection tanker has grown to a

massive vehicle capable of carrying up to 36,000 litres! Not very

practical for remote country lanes and some farm access! |

MMB driver Bob Poole and the business end of a modern

farm collection tanker. |

On arrival at each farm, the milk in the farmers tank is agitated, a

sample is taken and the temperature checked.

It is then metered via a computer onto the lorry and a printout of the

litres, temperature and time of collection etc. is given to the farmer.

Back at the depot or dairy, a printed list of farms collected by the

driver, with litres, temperatures and times etc. is handed to the supervisor

or dairyman so that any problems can be traced right back to an

individual farm. |