|

There

cannot be many people who have lived in and around Rooksbridge during the

last

100 years or so, whose lives were not touched by the existence of

the Cheddar Valley Dairy Company.

I worked at the dairy for 33 years from 1960 -1993.

Some of my colleagues had been there far longer! During that time I got

a fairly general education in the goings on at the dairy!

Apart from a spell of five or six years in maintenance I was employed as

a driver.

My regret now is... I never took many photos or kept any kind of

records while I was there!

So from memory

and with the help of Mr Richard Brown and others, I hope here to give an outline of the

history, the work and some of the characters on which the dairy depended.

If you have a story to tell about the dairy, or can add to this history

of the Cheddar Valley Dairy. Do please get in touch.

John (Fred) Rigarlsford

During its 120 year history, the dairy situated

in the heart of dairy country, would become one of the largest

manufacturers and suppliers of cheddar cheese, butter, cream and other

dairy products in the south west. It also became one of the largest

employers in the area. Many of its workers and sometimes their families, spent their whole working lives

there.

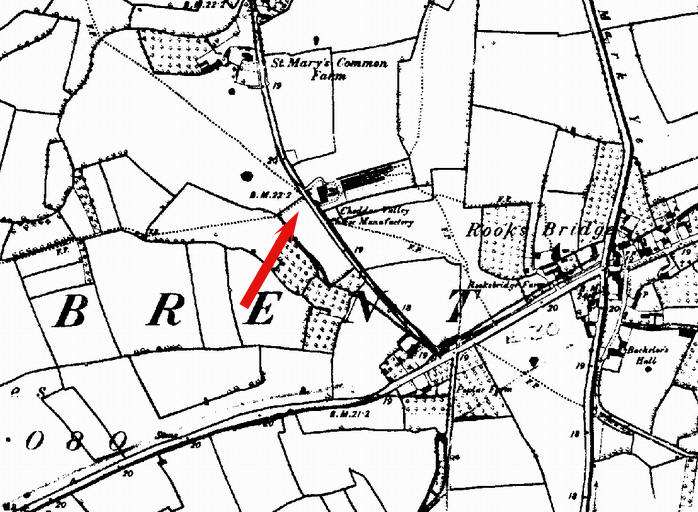

From an OS map of 1880. Note the

footpaths radiating across the fields from the dairy. In the days before

motor transport was introduced, many workers would walk from surrounding

villages to work at the dairy.

|

The dairy circa: 1900

Photo courtesy: R Brown.

|

A brief

History

Situated in 'Factory Lane' on what is

now the site of the 'Mendip Business Park' in Mendip Road, the

dairy was first established by two local farmers Messrs Arney and

Clothier. And later, joined by Mr John Wood of East Brent

(John Wood moved back to Derbyshire in about 1892, Where he

subsequently had a milk business in Ashbourne before being put out

of business when Nestle built a factory in the town) Andy Wood.

|

Edward Clothier and William Chappel Arney

built the cheese "Manufactory" in 1870 at the site of a farmhouse in Factory

Lane. By 1874, Messrs. Clothier and Arney were manufacturing cheese

at the factory with milk supplied by local farmers, from an estimated 850 cows . At times there were also upwards of 500 pigs

kept there, to be fattened on the whey.

Because of the abundance of whey and skimmed milk from the production of

cheese and cream etc. most farmers in the area kept a pen or two of

fattening pigs.

In fact a dedicated pig fattening unit was built opposite

the dairy in 1935, where until 1980 upwards of 1000 pigs at a time were fed with whey

piped direct from the factory into the pig houses.

By 1889 the dairy was occupied and run by Messrs Boley and Wood.

The Cheddar Valley Dairy Towards the end of the

1800's the production of butter, cream and milk was growing and it became

known as the Cheddar Valley Dairy Co Ltd when the Cox family,

among them William and Mary Cox from High Littleton became major

shareholders.

They had set up ‘Cox and Sons’ Cardiff Milk

Supply. with a number of retail shops and outlets in the City of Cardiff.

|

The milk for Cardiff, supplied by CVD for many

years, was sent in churns via Rail from

Brent Knoll Station. In the early days the churns were transported to

the station by

horse and cart.

This photo of a proud

George

Emery is undated. Note the 17 gallon churns riding with no visible

means of constraint ! The lorry was built on what appears to be a 6

wheeled chassis? Which would have been unusual in those days.

Photo courtesy: Margery Fear. |

In the early 1900's, The Cox family were

joined by directors, Gilbert Brown of Cheddar and John Counsell of the

'Manor' Lympsham, who remained active in the company until the 1960's

Kelly directory of 1902 states that the

manager of CVD in 1901 was a Walter Mitchell?

|

Soon after this

in 1904

Charles Emery

become the manager, and then a director of the Cheddar Valley Dairy.

'Charlie' ran the dairy for just over 50 years through two world

wars until he died in 1954. Charles and his older brother Fred

had began a dairy business at Manor Farm Tarnock in the early 1900's.

Charles was regarded as an expert cheese maker and pig breeder.

He was also a prominent Freemason.

Photo courtesy: Margery Fear.

[The Emerys were a large and active

family in the village. For more...Click

here] |

About 1934, a managers house, 'Brent Holme' was built on the site.

And the old existing farmhouse and living quarters became part of the

factory, housing the extended cheesemaking room and

cheese store.

| When Charlie Emery died in

1954 his

son David took over the management of the dairy.

Photo courtesy: Margery Fear.

|

|

In 1958, The Cheddar Valley Dairy was taken over by Horlicks Farms and Dairies of Slough.

They also owned the cheese dairy and

a Cattle breeding Station at 'Hort Bridge' Ilminster Som.

(The cattle breeding centre at Ilminster provided an Artificial

Insemination service to farmers).

|

By 1959 Richard Brown was

manager and Geoffrey Raffel was the under manager.

Richard Brown remained manager until the late 1980's when he took up a

post with Chewton Mendip Dairy as a cheese consultant.

Here we see: Richard and Mrs

Brown, Geoffrey Raffell and Gilbert Brown

Photo courtesy: R Brown.

|

The expansion into

doorstep deliveries. After the war, improved hygiene and

distribution standards were introduced countrywide. Previous to this,

milk was delivered daily to dairymen and customers mainly,

un-refrigerated and in churns. Improved methods of transport, pasteurisation, cooling of milk and sterilising of equipment

made processing more efficient, making it possible for milk

to be stored for longer and distributed over greater distances, .

In addition to Cheese, cream and buttermaking, the installation of an APV continuous pasteuriser and

a

mechanised bottling system in the 1950's and early 60's enabled a period of

expansion by the Rooksbridge dairy into further retail and doorstep deliveries

etc.

Beside supplying bottled milk etc. to independent dairymen, a number of local dairy businesses were acquired or merged with

the existing retail depots and outlets owned by Horlicks and CVD.

Greenway Dairies of Taunton, Courts Dairy at Burnham on sea and Rawles Dairy at Minehead were bought

and run by CVD. As were dairies operated by Highbridge Bacon Co. Ltd at

Highbridge and Weston Farmers Dairy in Locking Road Weston super mare.

By the early 1960's, the Horlicks Farms and Dairy division would have retail

rounds depots

and shops

at: Burnham, Cheddar, Clevedon, Glastonbury, Nailsea, Taunton and Weston super

mare. To supply all these depots etc. The Rooksbridge dairy was now employing over 120 people and new

offices, maintenance workshops, canteen

and restroom facilities were built in 1968. And a brand new high speed

bottling unit was planned.

The acquisition of Taylors Dairy of Weston super mare

was one of the early larger retail dairies to be bought by CVD.

This

combined with the Weston Farmers Dairy, would under the name of 'Horlicks

Farms and Dairies' become the largest

doorstep delivery operation in Weston.

At its peak in the 1970's, to serve Weston alone, a fleet of nearly 60 milk floats would

operate daily from the depot at Locking Road.

The Locking Road premises became the Headquarters of the Somerset retail

operation managed by Mr John Horlick. (No relation)!

|

Seen here are Mr Cyril Taylor and some of the staff and

milk floats from Taylors Dairy on display at the annual June Dairy

Festival in Weston super mare in the 1950's

Photo courtesy: R Brown. |

|

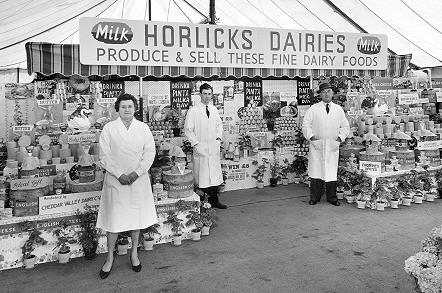

A display of Cheddar Valley Dairy

products at the Dairy Festival.

Included:

Traditional truckles of cheese in 60lb, 9lb and 4lb sizes. Milk,

butter and cream including novelty 'midget cheddars' and 'Clotted

Cream by post', popular with visitors.

Cyril

Taylor (Weston retail manager) aided by a young assistant and Mrs

French (Manager Cheddar)

Photo courtesy: R Brown.

|

Cheese making.

The end of an era!

In 1972 the Horlicks Company was

bought out by the Beecham group. Mainly for its Pharmaceutical division based

at Slough. The sale included the Horlicks Farms and Dairies division including

the Rooksbridge dairy and

its retail

division. and also the

Cheese Dairy and the Cattle Breeding centre at Hort Bridge, Ilminster.

Maybe we had not realised it at the time, but the

British dairy industry had reached its peak at around this period.

With increasing foreign dairy produce imports and competition from supermarkets,

with their strong

selling and purchasing powers adding further pressures on producers and

suppliers margins... the decline in doorstep deliveries and the

profitability of the old

traditional ways of producing dairy products had

begun. Changes had to be made to the way dairies operated.

Butter and cream manufacturing were among the first dairy products to

be phased out at Rooksbridge. These had always been made in small batches,

in keeping with the traditional farmhouse style, which was labour

intensive.

Next came the end

of traditional cheese making at Rooksbridge after over a 100 years.

In 1981 cheese production ended at Rooksbridge and was moved to Ilminster.

In order to stay viable, Beechams had invested more than a million pound in

upgrading the cheese making operation at the Ilminster dairy. A fully

automated mechanical cheese making process was installed. Which when

running, virtually mass produced block cheese with hardly any manual intervention!

Milk went in one door and literally 'supermarket ready' vac-packed blocks

of cheese came out of the other!

Another effect of ending cheese, cream and butter production at

Rooksbridge was.... skimmed and semi-skimmed milk for bottling had to be

bought in! This was at a time when the promotion of low fat products was

getting into full swing.

The early 70's had also seen the phasing out of traditional churn collections from the

farm. Local farmers had to install refrigerated bulk tanks from which

the milk would be collected by tankers operated by the Milk Marketing

Board.

Due to the extra expense of installing the new tanks and access needed

etc. many of the small dairy farmer suppliers, were forced to called it a

day!

Because of the way that raw ex-farm milk was now collected and

distributed under the national control of the Milk Marketing Board. The long

standing contracts

and connections between the many local farmers and CVD had to be ended.

Milk would now have to be bought in by tanker from the MMB. with no

choice of suppliers as before.

By now the dairy was solely reliant on liquid milk products and

sales.

Milk was produced in:

- bottles for doorstep delivery,

- non-returnable polyjars, cartons mainly to shops and

supermarkets

- and 3gall and 5

Gallon milk-pak containers for catering establishments

| To keep the business viable, a purpose built

Bottling Hall was erected on land adjoining the dairy. It was

commissioned in 1969

With the installation of a high speed bottling

line, capable of an output of 1000 crates an hour, production was able to keep up with the increasing demands

made by supplying a wider area and larger wholesaler contracts.

Photo courtesy: R Brown.

|

|

.

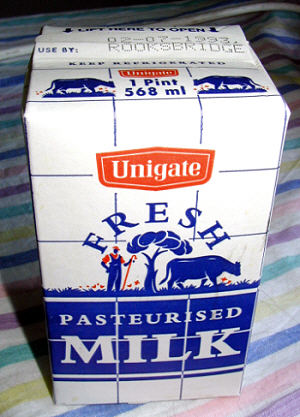

'Unigate Dairies'.....

the final chapter!

By 1985, The Rooksbridge production Dairy and all its retail depots

and outlets

had been bought by Unigate.

Unigate, a large National dairy company which had

previously been formed by the amalgamation of the old United Dairies and

the Cow and Gate Dairy.

With bottling plants and retail depots nationwide, those in the south and

west were at, Totnes in Devon, St Erth in Cornwall, Marshfield in Sth Wales, Hanworth

in Surrey and several smaller plants along the South Coast. Unigate also

operated the St Ivel brand. producing Yoghurts, butter, cheese and other dairy

products at factories at Evercreech and Wooton Bassett etc.

The acquisition of the Rooksbridge operation gave Unigate a greater presence in

Somerset area, to add

to its national coverage of milk sales and dairy products etc.

Soon after Unigate took over the dairy, many changes were made to many

of the existing buildings and production processes.

'Brent Holme' the former managers House, was now being used for offices. A

large extension was added to this and became, the 'Wessex Area' headquarters

for all Unigate operations in the South West. At about this time a fully

automated carton and poly-bottle filling area was built where the old

cheese room had been. The building also housed new offices for

production, transport, engineering and laboratory managers etc.

The Rooksbridge dairy was now distributing over 26000

gallons of milk daily to retail depots extending to the whole of Somerset,

Parts of Devon, South Gloucester and into Wiltshire.

In addition to the former Horlicks retail depots, the dairy was also now

supplying the three original Unigate depots in Bristol, at Ashton Gate, St Phillips and

Stoke Bishop. And also at Bath and Swindon. The Rooksbridge dairy also helped to supplement

production of the Totnes and Marshfield Dairies.

Wholesale deliveries in non returnable containers were also being

delivered direct to shops including large contracts with Tesco and Sainsburys

supermarkets daily.

|

A 42 ton refrigerated trailer

carrying up to 1000 crates being unloaded at Stoke Bishop.

Bristol

Photo. J Rigarlsford |

Sadly, under Unigate, the investment in expansion

and the viability of the Rooksbridge site was not to last. As with many

dairy companies, foreign imports and the decline in doorstep sales and

the increasing demands from the supermarkets for lower milk prices and

produce, was to lead to crisis for much of the dairy industry and

indeed the dairy farming and agricultural economy of the country in general.

To try to keep going, Unigate sold off its retail and production

dairies north of the M4. Concentrating its efforts on its production and

retail operations in the South and West of England. Of these, gradually

all the production dairies along the South Coast at Worthing, Portsmouth, Southampton

and Bournemouth etc. would eventually be shut down.

|

At the end of production, on the last day

at the Rooksbridge dairy. A few empty commemorative

cartons dated 02-07-1993 "ROOKSBRIDGE" were run through the

machine before it was finally switched off.

(I managed to grab one)!

Photo: J Rigarlsford. |

The fateful day for the dairy at Rooksbridge came in

July 1993. After over 120 years, production ceased at Rooksbridge on July 2nd. The Rooksbridge

production and any moveable equipment was shared between the remaining Unigate

bottling factories at Totnes in Devon and Marshfield in South Wales.

Even this could not save a once huge company such as

Unigate as a productive dairy operation. It eventually sold out its

liquid milk division to Dairy Crest in 2000. Even the St Ivel operations

at Evercreech, Wooton Bassett, St Erth and Totnes were later reduced or closed

down.

While other national dairy companies phased out doorstep

deliveries, Unigate vowed to keep them going. So far, Dairy Crest

has continued the doorstep delivery rounds. (But who knows

for how long)?

Sadly, I believe what is left of the company now goes

under the name of 'Uniq' and makes sandwiches for 'Marks and Spencer'!

Mendip Industrial Estate.

The old dairy site lay empty and declined badly for a couple

of years, suffering from unofficial visits by gypsies, scrap merchants

and other vandals!

| In 1995 the site was bought and developed as an Industrial

Estate by Malcolm King Estates.

Malcolm King

piloting his private helicopter into the estate on one of his

regular visits.

Photo: J Rigarlsford |

|

Uncannily, The first small company to set up on the new site

is

a cheese packaging operation. Its Unit happens to occupy what was once the

old cheeseroom area! So cheese has come back to Rooksbridge in a

roundabout way!

The other main occupant of the site at the time was 'Hillcrest' a

company that repaired and serviced Ex fleet hire cars in preparation for

auction etc.

Regrettably, with the site containing hundreds of vehicles, security was

a big problem.

Eventually 'Hillcrest' folded.

Mendip Business Park

|

In 2003 the site was acquired and developed further by Tim

Roper of Mendip Estates.

Photo:

J Rigarlsford |

Security and renovation of the existing buildings were

improved. Many of the buildings such as the former bottling hall

and offices etc were divided into smaller units and a number of new

units built.

This has brought a number of diverse businesses and new

employment to what was the old dairy site.

These include, Engineering, Joinery, Computer, Heavy

plant and forklift training, Organic food producers etc. among many others

which can be found in the business page

of this website.

To be continued.....

|