A Day at the dairy!

The following essay, written as a school project in 1940, gives a look at what a typical day at the Rooksbridge dairy might have been like at the time. as seen by a young London evacuee.

"Inside information"

on work in:

A MILK FACTORY.

on work in:

A MILK FACTORY.

VERY few Londoners ever bother to think of how their morning pint of milk really gets to their doorstep. Little do they realise, until they have lived in the country and seen it in action, the enormous organisation that is required to take their pint of milk from the cow to their doorstep. On being evacuated I was billeted with a dairy-man, and I was thus able to learn quite a lot about the milk industry, and was able to go over the Cheddar Valley Dairy Company's milk factory at Rooksbridge.

Cows are milked at dawn, and also again at dusk. The milkers turn out in all weathers, with their dog in their carts, each carrying two churns, and sit on their peculiar stools milking. The cows become accustomed to milking and assemble in a corner of the field. Often nowadays the herds return to the farm-houses, where they are milked by electricity. The churns, each containing some 12 gallons of milk, are placed on wooden benches at the roadside, ready to be collected by vans. The next stage, the collection of the churns, is done by the factory itself. (A "factory" here is not a manufacturing workshop but a collecting centre). Vans are sent out to collect the churns from the neighbouring district. Each full churn is replaced by an empty, clean one. These vans rush the milk back to the factory - rush is the correct word, for one never sees a milk van going slow.

In the evening the milk is brought into the factory. The vans back against a raised platform and the full churns are unloaded and inverted over a large tank, into which the milk drains. This tank supplies the various plants of the factory. The churns themselves are placed on one side to be washed. This is accomplished by inverting them over a jet of steam and swilling them with a hose. The jet, rising from the floor, makes an almost unbearable noise. The churns are not allowed to dry before they are rushed out again, once more to be filled with milk. The whole cleaning process is only a matter of a few minutes.

The milk itself is fed to the pasteuriser. This machine brings the milk up to boiling points during its passage through it, thus destroying any disease. Now the milk is very hot. In this condition it is passed through the separator, the cream running out at one pipe and ordinary milk out at the other. skimmed milk results; it comes when ordinary standard milk is separated to give cream for butter-making. To cool the milk it is dropped over a series of pipes about 2ins. in diameter, filled with freezing brine fed from a freezing plant. The milk is collected in another tank, from which it can be run into fresh churns or loaded directly into the railway containers to be sent to London. The churns pass out of the other side of the factory into vans to be carried to the neighbouring station, in my case Brent Knoll, from where it is sent to London to be bottled and delivered. The power for all these various plants comes from a huge boiler. This furnace is far away from the factory itself, for the resulting heat would not have a favourable effect on the milk in summer. The atmosphere in the factory is one of continuous hurry and bustle. Nobody seems short of some task or other. The noise is terrific. The machinery rattles continuously; the cooling plant pumps away methodically; whilst escaping steam from the pasteurising plant and the jet for cleaning the churns is sufficient to augment all the other noises into one big din. Another noticeable fact is the ease with which the churns are moved. The floor is made throughout of iron grating to facilitate their easy movement. The workmen, moreover, are extremely clever at rolling them, whether full or empty. This may look simple to townsfolk, but to roll a full churn is a very delicate job. The railway provides all transport to London, the chief consumer for all South England. Thus the milk is taken to the towns. Never is there a shortage; seldom is any wasted. The milk once bottled is delivered to the householders in the morning, the whole process taking place in less than 24 hours.

P. MANNERS (L.6 Modern)

Cows are milked at dawn, and also again at dusk. The milkers turn out in all weathers, with their dog in their carts, each carrying two churns, and sit on their peculiar stools milking. The cows become accustomed to milking and assemble in a corner of the field. Often nowadays the herds return to the farm-houses, where they are milked by electricity. The churns, each containing some 12 gallons of milk, are placed on wooden benches at the roadside, ready to be collected by vans. The next stage, the collection of the churns, is done by the factory itself. (A "factory" here is not a manufacturing workshop but a collecting centre). Vans are sent out to collect the churns from the neighbouring district. Each full churn is replaced by an empty, clean one. These vans rush the milk back to the factory - rush is the correct word, for one never sees a milk van going slow.

In the evening the milk is brought into the factory. The vans back against a raised platform and the full churns are unloaded and inverted over a large tank, into which the milk drains. This tank supplies the various plants of the factory. The churns themselves are placed on one side to be washed. This is accomplished by inverting them over a jet of steam and swilling them with a hose. The jet, rising from the floor, makes an almost unbearable noise. The churns are not allowed to dry before they are rushed out again, once more to be filled with milk. The whole cleaning process is only a matter of a few minutes.

The milk itself is fed to the pasteuriser. This machine brings the milk up to boiling points during its passage through it, thus destroying any disease. Now the milk is very hot. In this condition it is passed through the separator, the cream running out at one pipe and ordinary milk out at the other. skimmed milk results; it comes when ordinary standard milk is separated to give cream for butter-making. To cool the milk it is dropped over a series of pipes about 2ins. in diameter, filled with freezing brine fed from a freezing plant. The milk is collected in another tank, from which it can be run into fresh churns or loaded directly into the railway containers to be sent to London. The churns pass out of the other side of the factory into vans to be carried to the neighbouring station, in my case Brent Knoll, from where it is sent to London to be bottled and delivered. The power for all these various plants comes from a huge boiler. This furnace is far away from the factory itself, for the resulting heat would not have a favourable effect on the milk in summer. The atmosphere in the factory is one of continuous hurry and bustle. Nobody seems short of some task or other. The noise is terrific. The machinery rattles continuously; the cooling plant pumps away methodically; whilst escaping steam from the pasteurising plant and the jet for cleaning the churns is sufficient to augment all the other noises into one big din. Another noticeable fact is the ease with which the churns are moved. The floor is made throughout of iron grating to facilitate their easy movement. The workmen, moreover, are extremely clever at rolling them, whether full or empty. This may look simple to townsfolk, but to roll a full churn is a very delicate job. The railway provides all transport to London, the chief consumer for all South England. Thus the milk is taken to the towns. Never is there a shortage; seldom is any wasted. The milk once bottled is delivered to the householders in the morning, the whole process taking place in less than 24 hours.

P. MANNERS (L.6 Modern)

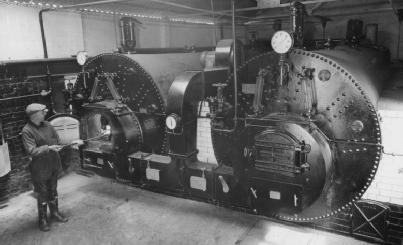

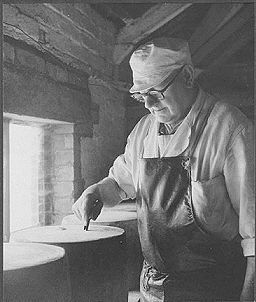

A typical day at the dairy would start very early in the morning, say at 4.30am, when the boilerman would get up steam ready for the cheesemaker.

The Early Shift!

During the 1950's these boilers were converted to heavy fuel oil burners and were virtually able to maintain the correct head of steam unsupervised.

It saved a lot of raking and shovelling coals !

Part of the early morning boilermans duty, was to get a good head of steam to heat the milk in the cheeseroom ready for the Cheesemaker to add the starter when he came in.

The Cheese maker would arrive at about 5-30am to add a rennet starter to the heated milk which would begin the 'Cheddar-ing' process.

Seven 1000 gall milk vats on the upper deck held milk that was heated and stirred. And at the correct temperature, starter would be added . (Getting the amount of starter and the temperature correct is part of the skill of the cheesemaker)!

Once the first part of the process was complete, the curdled milk was drained into the lower cheddar-ing vats, where the whey drained from the cheese. The solidified curd is then cut with large knives, into manageable blocks and continually turned and stacked until all the whey is drained. When it is then milled and the salt added.

The milled cheese is then packed into 60lb truckle moulds lined with cheesecloth. These cheese moulds were then pressed for several days in huge gang presses to compact and remove any excess moisture from the cheeses.

Seven 1000 gall milk vats on the upper deck held milk that was heated and stirred. And at the correct temperature, starter would be added . (Getting the amount of starter and the temperature correct is part of the skill of the cheesemaker)!

Once the first part of the process was complete, the curdled milk was drained into the lower cheddar-ing vats, where the whey drained from the cheese. The solidified curd is then cut with large knives, into manageable blocks and continually turned and stacked until all the whey is drained. When it is then milled and the salt added.

The milled cheese is then packed into 60lb truckle moulds lined with cheesecloth. These cheese moulds were then pressed for several days in huge gang presses to compact and remove any excess moisture from the cheeses.

Ernie Popham (Rooksbridge) stoking the coal fired boilers.

photo: courtesy R Brown.

photo: courtesy R Brown.

The Cheeseroom Circa 1947 photo: courtesy R Brown.

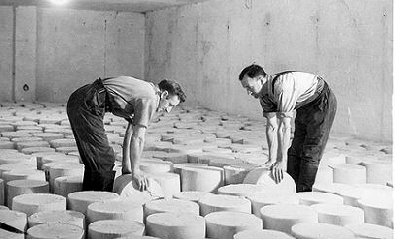

When the cheeses were removed from the presses, they were stamped with vat numbers, dated and then placed into store.

Here the cheeses were turned daily while maturing, sometimes up to a year or more, depending on the flavour required.

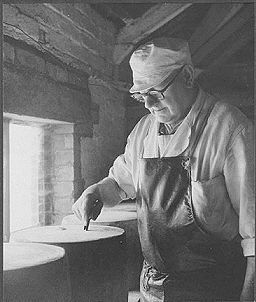

Once the stored cheeses reached the age of maturity and flavour required. Using his cheese sampling plug cutter tool. The cheesemaker would sample the batch for flavour and texture etc. This enabled him to know how a particular batch would grade when tested by the wholesalers cheese grader.

Frank Page sampling a batch of cheeses

Frank Page sampling a batch of cheeses

Here the cheeses were turned daily while maturing, sometimes up to a year or more, depending on the flavour required.

Once the stored cheeses reached the age of maturity and flavour required. Using his cheese sampling plug cutter tool. The cheesemaker would sample the batch for flavour and texture etc. This enabled him to know how a particular batch would grade when tested by the wholesalers cheese grader.

Frank Page sampling a batch of cheeses

Frank Page sampling a batch of cheeses

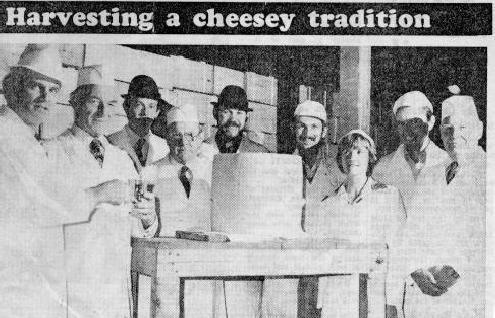

Head cheesemaker Jim Andrews came out of retirement in 1981 to dress and prepare the very last Harvest Home cheese, and to receive a tankard on his retirement, from manager Richard Brown.

Also in the photo are: Steve Perkins. Production Manager, Stan Burden. Engineer, Dennis Cottle. Area manager, Gilbert Pike. Cheeseroom foreman, Margaret Poole. Laboratory, John Holdenby. Bottling supervisor and Pete Lewis. Customer Liason.

photo courtesy: Western Daily Press.

Also in the photo are: Steve Perkins. Production Manager, Stan Burden. Engineer, Dennis Cottle. Area manager, Gilbert Pike. Cheeseroom foreman, Margaret Poole. Laboratory, John Holdenby. Bottling supervisor and Pete Lewis. Customer Liason.

photo courtesy: Western Daily Press.

While the cheese made by CVD was usually made as 60 lbs traditional farmhouse truckles, gradually, with the demand for pre packed cheese for supermarkets etc, block cheese was increasingly produced in 40 lbs vacuum packed blocks.

Until the mid 1950's, batches of Caerphilly, Cheshire and Double Gloucester were also produced.

At its peak, the dairy was manufacturing over 18,000 tons of cheese per year.

To expand production further would have cost over £500,000 for a complete refit of equipment and buildings. The decision was made to expand cheesemaking facilities at the Horlicks Dairy in Ilminster.

And in 1981 after more than a hundred years, cheese making at Rooksbridge ended!

Until the mid 1950's, batches of Caerphilly, Cheshire and Double Gloucester were also produced.

At its peak, the dairy was manufacturing over 18,000 tons of cheese per year.

To expand production further would have cost over £500,000 for a complete refit of equipment and buildings. The decision was made to expand cheesemaking facilities at the Horlicks Dairy in Ilminster.

And in 1981 after more than a hundred years, cheese making at Rooksbridge ended!

1964 and two proud cheesemakers claim another clutch of awards!

Cheesemakers Stan Body and Jim Andrews show off their Mid Somerset show trophies

photo: courtesy R Brown.

|

|

Cheese Making

Cheesemaker Stan Body and assistant turn the cheeses in store.

A standard truckle of Cheddar cheese weighed 60 lbs. 9 lbs and 4 lbs truckles were also made, along with miniature 1/2 lbs and 1 lbs waxed cheeses mainly for the tourist trade.

The Harvest Home Cheese

It was always tradition, that a special giant 112 lbs cheese was made and presented to the East Brent Harvest Home every year! (The last of these was made and paraded in 1981).

| William's letters home |

| Bessies Poems |

| Edwards Letters Home |

| Cheddar Valley Dairy |

| EBPC Archives |

| Methodist |

| Rooksbridge baptist chapel |

| Shops & Tradesmen |

| Rooksbridge Post Office |

| St Marys |

| Village pump |

| War memorial |

| Wellington Arms |

| Workhouse |

| A day at the dairy |

| vicars |

| WardensAcc |

| deanery mag |

| WW1 Exhibit |

| Workhouse Life |

| War Memorial |

| Cheddar valley Dairy |